Last year alone, ACMprovided cleanroom consulting & training to over4000 people working in cleanrooms, includingtesting, access badging, violation reporting and providing key metrics for our clients use.

Cleanroom Consulting & Training

As you can imagine, with over 33 years of cleanroomexperience, our Managers have done and seen it all. One of the areas ACM prides itself on is being best atdelivering cleanroom consulting & training classes.

Our trainingclasses may be tailored to meet the demands and scope of any clean-build project or manufacturing customer

ACM will train your groupfor:

- Clean-Build Protocol and customers in the manufacturing mode.

- Training Classes may consist of Cleanroom History, Cleanroom Classifications,Cleanroom Protocols, Cleanroom Gowning demonstrations, acceptable Cleanroom Behaviors, Aseptic Practices and Good Documentation Practices. (GDP’s)

ACM Training Managers Demonstrate Cleaning Procedure to the CePAT Team in Ghana, Africa Remotely from ACM’s Offices in PA.

CLEAN-BUILD- PROTOCOL TRAINING

Our Protocol training aligns with construction schedules and project management requirements.

Protocol Level 1– Weather Tight

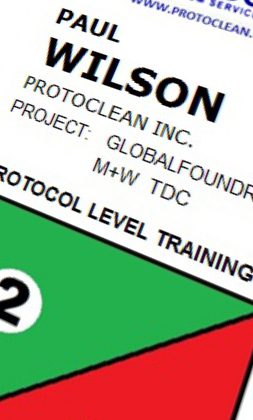

Protocol Level 2– Utilities Hook-up

Protocol Level 3– Cleanroom Interiors

Protocol Level 4– Filter Installation

Protocol Level 5– Certification and Test

Protocol Level 6– Tool Hook-up

Protocol training also encompasses:

- Access Badges or stickers

- Control and monitoring of cleanroom entrance – areas.

- Definition and enforcement of protocol levels and the standards of cleanliness.

- Providing Posters and signage to control behaviors.

- Tracking and Enforcement of cleanroom violations / providing re-training.

- Dirty work permit management or PEPs (Protocol Exception Plans)

- Violation databasewithdaily / weekly / monthly project metrics

- Coordination of all cleanroom cleaning schedules and cleaning

- Launderables and change-outs

- DI (de-ionized) water system set-up for cleaning

- Proper gowning and use of cleanroom consumable supplies (headcovers, facemasks, shoecovers, smocks, sleves, overalls, knee boots, gloves,Tyvek tape, etc.)

- Drinking water and hydration.

ACM’s cleanroom rule: “Cleanroom Protocol is followed 7 days a week, 24 hours a day.”

CLEANROOM TRAINING FOR PRODUCTION COMPANIES

ACM offers training to production personnel, supervisors, managers of companies who have cleanrooms for their manufacturing and R & D processes. The training classes consist of:

- What is a Cleanroom?

- Mechanics of a Cleanroom

- Classification of Cleanrooms

- ISO Cleanroom Standards

- Cleanroom Behavior

- Cleanroom Protocols

- Cleanroom Gowning

- ESD in Cleanrooms

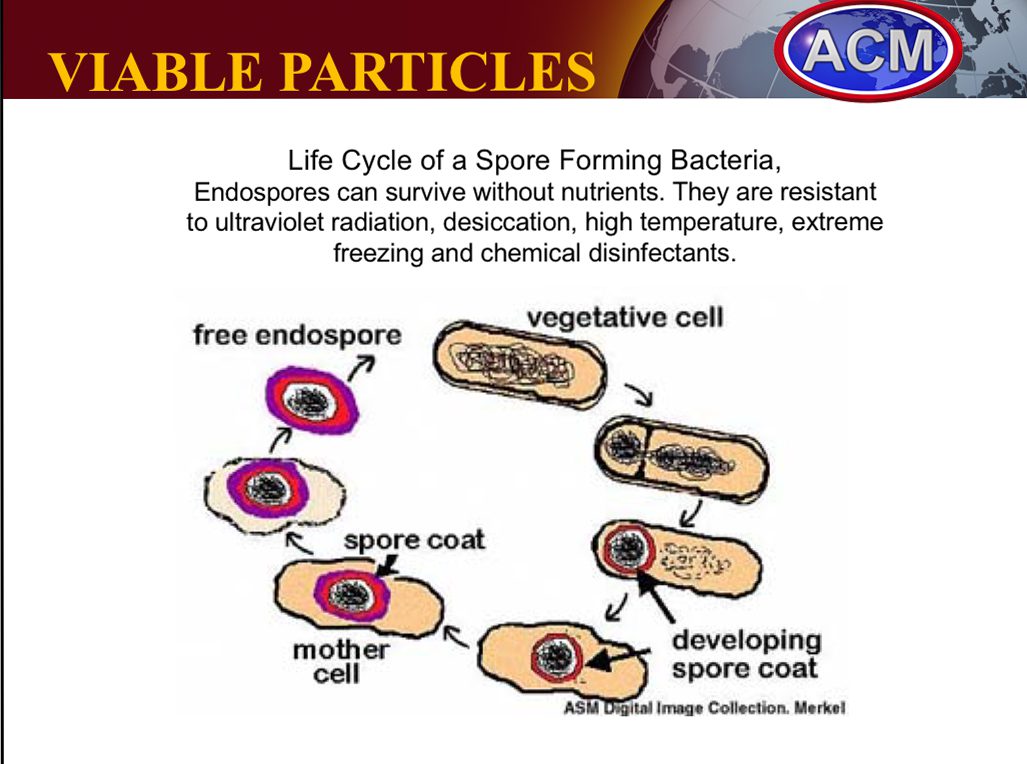

- Microbiology

- Aseptic Techniques

- GMP Documentation requirements for Cleanroom Cleaning

Why Choose ACM?

We pride ourselves on being abusiness partner that quality assurance, purchasing and facility managers can rely on. Everyone agrees, ACM’s combined knowledge and experience is unmatched in the cleanroom industry. For more information on how ACM can help you plan your training, “Contact” us now.