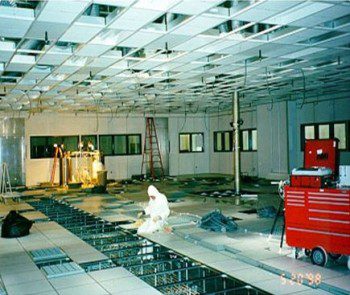

CLEAN-BUILD CONSTRUCTION PROTOCOL

ACM’s Clean-Build division offers Protoclean protocol services for cleanroom construction according to ISO 14644-4 standards. ACM partners with the contractor and customer to establish and schedule protocol levels 1 through 5 for all phases of clean-build cleanroom construction. Protoclean’s progress, tasks, reports and environmental measurements are captured and stored on our own secure proprietary software system, making vital data easily accessible to the customer and contractor in real time.

MOBILIZATION

ACM is mobilized and on site as soon as the interior building is weathertight and installations of return ducts, process piping, unistrut, pipe hangers, and other utilities downstream of the clean air are started.

Equipment and Tool Hook-up Protoclean Protocols are executed once the facility passes the As Built Certification. At the completion of Tool Hook-up, a second Certification is performed under At Rest Conditions.

Protoclean is quality control for clean-build construction of cleanrooms.

Reasons Industry Leaders Utilize ACM’s Protoclean Protocol

A leader since 1985  of  “Outstanding Global Construction Results.”

Veteran Cleanroom Protocol & Cleaning Team

Globally Recognized Training Programs

Quick Mobilization Turn-Key Project Startup Team

Quality Focus ISO 9001:2015 Certified and Member of US TAG

Unmatched Procedural Knowledge and Technical Data Management

Broad Scope from Protocol and Cleaning Levels, to Tool Hook Up, Certification and Ongoing Monitoring.

ACM Assists the Contractor and Owner to Schedule Protocol levels, Requirements, Cleanings and also;

- Provides administrative support to management and teams.

- Sets training schedules to match construction schedules.

- Complete training of all Contractor personnel.

- Provides badging control and personnel database.

- Procures and provides all temporary protocol related signage.

- Provides supervision for temporary material entry and gown rooms.

- Monitors material and gown entry procedures.

- Establishes and maintains protocol violation database.

- Establishes dirty work permits for trades, area inspections and maintains database

- Monitors environment, including particle counts, temperature and humidity and maintains databases.

- Defines personnel and staffing levels.

- Procures and Manages all cleanroom and gowning consumable supplies.

Why Choose ACM’s Protoclean Service?

ACM’s Protoclean services for clean-build construction produces a cleanroom that continues to run clean year after year. Our Customers have over 99.4% yields the first run of product construction. These results are so significant that they produce 100s of millions of dollars in added revenue annually, making it well worth the small investment of building clean.

ACM Protoclean Protocol Services have been utilized at:

- Globalfoundries

- SUNY Technical Center

- Motorola MOS 12, 17 & 19,

- Intel

- Microchip

- AMG

- LSI Logic

- Applied Mechanical

- Hughes

- Jazz Semiconductor

- Magic Semiconductor

- UC Santa Barbara

- Northrop Grumman

- Western Digital

- White Oak Semiconductor

- Infineon Semiconductor

- and many more….

Paul Wilson

Global Director of Protoclean Protocol

ACM’s Protocol Manager consults with the customer on all Protoclean Levels as well as inspections, violations and cleaning warranting further action. ACM tracks all inspections, violations and cleaning on its own proprietary cloud-based software system, easily accessible to the customer and contractor. For more information or to speak with a Protoclean representative CONTACT US.